Plastic deformation in lightweight intermetallic composite materials

Themenbereich:

Modellierung & Simulation

Verantwortlicher Mitarbeiter:

Prof. Dr.-Ing. Erik Bitzek (Privatdozent)

Aviral Vaid

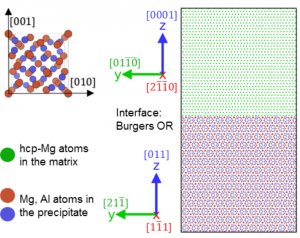

(left) Crystallographic structure of the complex intermetallic Mg17Al12; (right) Interface between Mg-Mg17Al12 in the Burgers orientation relationship between the matrix and the precipitate (A. Vaid).

Interfaces and dislocation-interface interactions play an important role for development of alloys with improved mechanical properties. Many alloys, however, are characterized by the presence of complex intermetallic phases. Examples, which are currently investigated at our institute, are die-castable Mg alloys for automotive applications. Here, the complex intermetallic γ-Mg17Al12 phase forms a connected skeleton that improves the creep resistance of this alloy. The Mg17Al12 phase is the most common intermetallic phase found in the Mg-Al alloy system. The phase has a complex bcc-like crystallographic structure (see figure) with a unit cell containing 58 atoms – 34 Mg atoms and 24 Al atoms.

With the on-going experimental work and the availability of semi-empirical interatomic potentials for the Mg-Al system, the focus of this project is on the Mg-Mg17Al12 model system. The ultimate goals of this project are a) to provide mechanistic insights and quantitative parameters for physics-based material models for the mechanical behavior of Mg alloys in automotive applications and b) to derive a general understanding of the impact of interfaces between complex intermetallic alloys and a metal matrix on the mechanical properties of intermetallic composite materials.

Related Publications:

- A. Vaid, J. Guénolé, A. Prakash, S. Korte-Kerzel, E. Bitzek [2019], „Atomistic simulations of basal dislocations in Mg interacting with Mg17Al12 precipitates“, Materialia 7, 100355, Link to paper